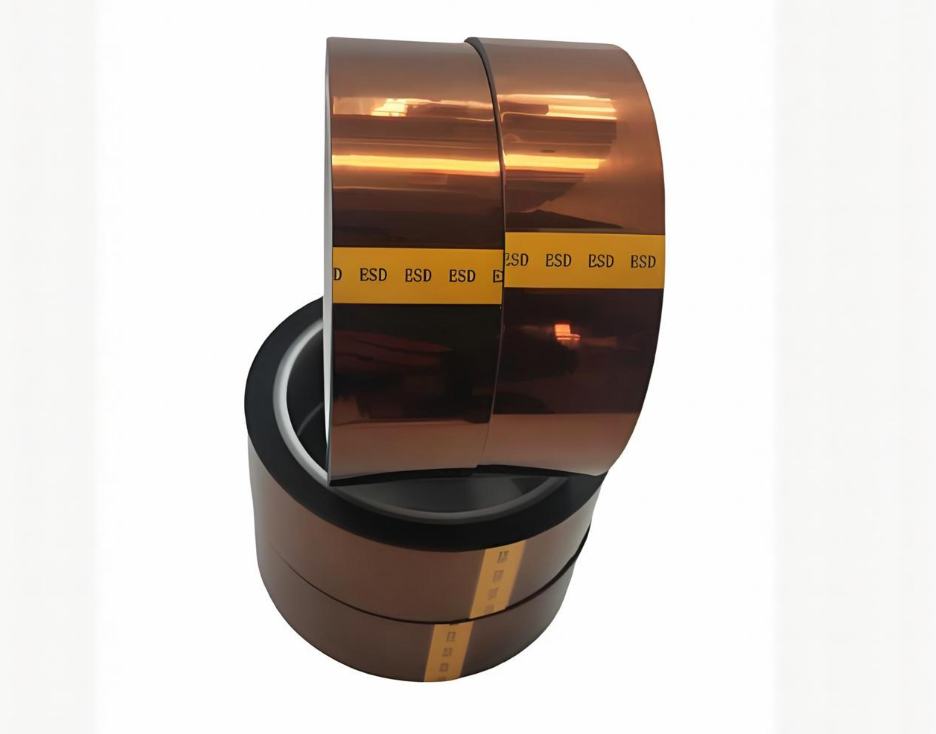

Anti-static polyimide tape is a high-performance tape specifically designed for static protection in the electronics industry. It combines the excellent high-temperature resistance of polyimide with anti-static properties, making it widely used in electronics manufacturing, semiconductor production, surface-mount technology (SMT), and other high-precision electronic device production processes. As electronic products become increasingly miniaturized and efficient, static electricity’s impact on components has become more significant. Anti-static polyimide tape, with its unique properties, has become an essential tool for static protection.

This article will detail the high-temperature resistance, static protection functionality, and applications of anti-static polyimide tape in electronic protection.

Basic Properties of Anti-Static Polyimide Tape

Anti-static polyimide tape is mainly composed of a polyimide film and an anti-static adhesive. Polyimide (PI) is a material known for its exceptional high-temperature resistance, chemical corrosion resistance, and electrical insulation properties, making it widely used in environments that require high temperature and stability. Anti-static polyimide tape not only retains these excellent characteristics of polyimide but also enhances its static protection capabilities by incorporating anti-static coatings or additives.

- High Temperature Resistance: Polyimide itself has excellent high-temperature resistance, typically able to operate stably within the temperature range of -269°C to 400°C. For high-temperature operations like soldering, pick-and-place, surface treatment, and other assembly processes, anti-static polyimide tape can withstand extreme temperatures without deformation or loss of adhesive properties.

- Static Protection: The surface of anti-static polyimide tape is specially treated to effectively suppress static accumulation and release accumulated charges, preventing electrostatic discharge (ESD) from damaging electronic components.

Applications of Anti-Static Polyimide Tape

- Electronics Manufacturing and Surface-Mount Technology (SMT)

In electronics manufacturing and surface-mount technology (SMT), anti-static polyimide tape is widely used for various static protection tasks. SMT, as the primary method of modern electronic assembly, involves high-density, high-precision electronic components, making electrostatic discharge (ESD) a significant threat to these components. Anti-static polyimide tape, with its high-temperature resistance and static protection capabilities, becomes an ideal material in SMT processes.

- Surface Protection: Anti-static polyimide tape is used to protect PCB boards or other electronic components during the manufacturing process, preventing damage from high temperatures or static electricity. It provides effective protection between heating elements and PCB surfaces, preventing static discharge from affecting sensitive components.

- Masking and Shielding: In SMT processes, anti-static polyimide tape is also used to mask and shield components or circuits, protecting them from damage during high-temperature operations. In particular, it can protect components from excessive heat or static damage during soldering operations.

- Semiconductor Industry

In semiconductor manufacturing, the need for static protection is extremely stringent because any electrostatic discharge (ESD) can cause irreversible damage to integrated circuits (ICs) or microelectronic components. Anti-static polyimide tape is widely used in the semiconductor industry, particularly during wafer processing, chip packaging, and transportation.

- Wafer Processing: Anti-static polyimide tape is commonly used to package and protect wafers, ensuring that wafers are not affected by static discharge during transportation, cutting, and processing. Its high-temperature resistance also meets the requirements for processing semiconductor components under high temperatures.

- Packaging and Testing: During semiconductor chip packaging and testing, anti-static polyimide tape effectively prevents static damage to chips. It remains reliable even under high-temperature conditions, ensuring smooth testing and packaging processes.

- Protection and Packaging of Electronic Components

The packaging of electronic components is a critical step in static protection, especially during transportation and storage. Anti-static polyimide tape provides extra protection for sensitive components. It is widely used in packaging and sealing to ensure that electronic components are protected from static damage.

- Packaging Sealing: Anti-static polyimide tape is often used to seal anti-static packaging bags, ensuring that components are not exposed to a static environment during transportation and storage.

- Component Bundling and Isolation: During storage and transportation, anti-static polyimide tape can bundle or isolate multiple electronic components, preventing them from generating static during contact, thus effectively protecting components from static interference.

- High-Temperature Soldering and Repair

The high-temperature resistance of anti-static polyimide tape makes it an ideal choice for soldering and repair operations. Particularly in high-temperature environments like surface-mount technology (SMT), reflow soldering, or wave soldering, anti-static polyimide tape can provide effective static protection while preventing electrostatic discharge (ESD) damage to components during these high-temperature operations.

Advantages of Anti-Static Polyimide Tape

- Excellent High-Temperature Performance

Anti-static polyimide tape can operate stably at extremely high temperatures, typically able to withstand temperatures above 300°C. It does not deform or lose its adhesive properties during soldering, heat treatment, or other high-temperature processes. - Outstanding Static Protection

Anti-static polyimide tape, through special surface treatments, can effectively release static electricity and prevent electrostatic discharge (ESD) from damaging sensitive electronic components. It is particularly suitable for static-sensitive applications in semiconductor and electronics manufacturing. - Strong Chemical Stability

Polyimide materials are known for their excellent chemical stability, enabling anti-static polyimide tape to resist a wide range of chemical substances. This makes it reliable in harsh environments where exposure to chemicals is common. - Good Electrical Insulation

Polyimide materials also offer excellent electrical insulation properties. Anti-static polyimide tape not only prevents static buildup but also provides electrical isolation, further protecting sensitive electronic components from electrical damage.

Conclusion

Anti-static polyimide tape is a unique, high-performance tape that combines superior high-temperature resistance with static protection, making it widely used in electronics manufacturing, semiconductor industries, electronic component packaging, and high-temperature soldering and repair operations. Its excellent high-temperature resistance, static protection, chemical stability, and electrical insulation properties make it an indispensable tool in modern electronic production and assembly. As electronic products become more sophisticated and efficient, the applications and importance of anti-static polyimide tape will continue to expand, ensuring the safety and reliability of electronic components across various industries.