At first glance, anti-static tape and regular adhesive tape may look nearly identical—transparent, flexible, and sticky. But when used in sensitive environments like electronics manufacturing, semiconductor processing, or cleanrooms, their performance and purpose diverge significantly. Understanding the key differences between these two types of tape is essential for engineers, procurement teams, and anyone responsible for maintaining electrostatic discharge (ESD) control.

This article provides a side-by-side comparison of anti-static tape and regular tape, explaining what sets them apart, where each should be used, and why choosing the wrong one can be costly.

-

Fundamental Purpose and Function

Regular tape is designed primarily for mechanical bonding—sealing, packaging, or fixing components. It provides adhesion but offers no protection against static electricity. In fact, most standard tapes are made of plastic materials (like polypropylene or PVC) that are insulators, and can generate or retain static charges when peeled from a surface.

Anti-static tape, by contrast, is engineered not only to stick, but also to control and dissipate electrostatic charges. Its core function is to minimize the risk of ESD events that can damage sensitive electronics. It’s a part of the larger ESD-safe ecosystem that includes anti-static garments, wrist straps, and grounded workstations.

-

Surface Resistivity: The Scientific Distinction

One of the most measurable differences between anti-static and regular tapes is their surface resistivity, which determines how they interact with static electricity.

| Tape Type | Surface Resistivity | Static Behavior |

| Regular Tape | >10¹² ohms | Insulative – accumulates static |

| Anti-static Tape | 10⁶–10¹¹ ohms | Dissipative or conductive – drains static |

Anti-static tapes fall into the dissipative (10⁶–10⁹ ohms) or conductive (<10⁶ ohms) categories, depending on the material and intended use. This means they safely release static over time or direct it away via a conductive path.

In contrast, regular tape can generate static voltages in the thousands of volts when unrolled, making it a hazard in static-sensitive environments.

-

Material Composition and Adhesive Type

Regular tape typically uses standard plastic films (e.g., OPP, PVC) and synthetic rubber or acrylic adhesives. These are not treated to prevent static buildup.

Anti-static tapes, on the other hand, features:

Static-dissipative or conductive base films (often treated PET or PI).

Special ESD-safe adhesives, such as conductive acrylics or silicones.

Optional top coatings to enhance conductivity or prevent contamination.

This engineered construction ensures that static does not build up or cling to the tape during application or removal—a common problem with standard tapes.

-

Visual and Physical Differences

Though not always easy to detect, some visual cues may help distinguish the two:

| Feature | Regular Tape | Anti-Static Tape |

| Appearance | Clear or opaque | Often amber, green, or tinted (PI/PET films) |

| Static Cling | High | Minimal |

| Noise when peeled | Loud (crackling) | Quieter, due to lower static generation |

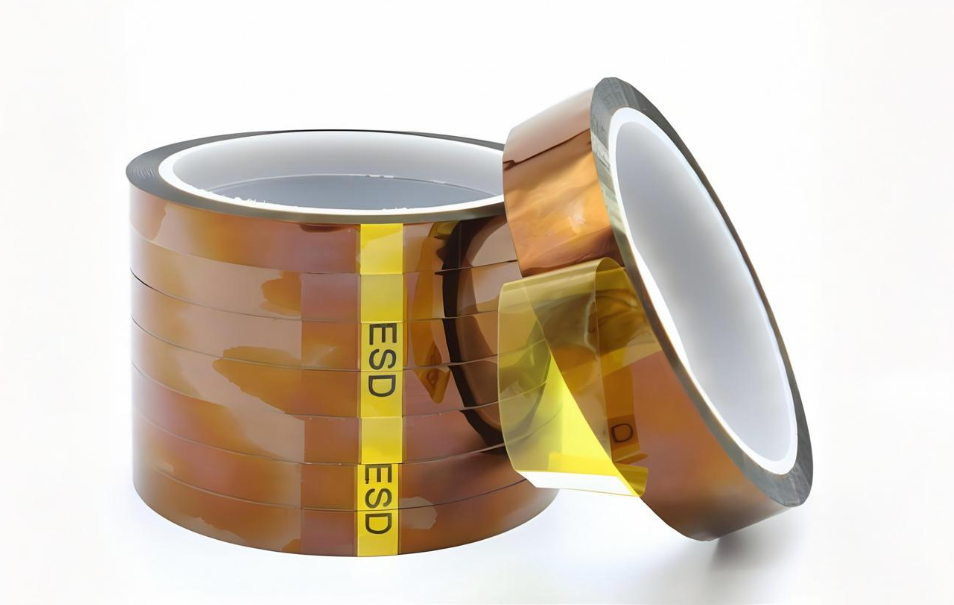

Some anti-static tapes also include ESD labeling or are packaged with anti-static liners, indicating their intended use in static-controlled environments.

-

Application Environment: Where Each Tape Belongs

Using regular tape in the wrong environment can have serious consequences—such as latent damage to semiconductors, reduced product yield, or even device failure in the field.

| Application | Recommended Tape |

| Home, office, general use | Regular Tape |

| Shipping non-sensitive items | Regular Tape |

| PCB handling or labeling | Anti-static Tape |

| Semiconductor packaging | Anti-static Tape |

| Cleanroom assembly | Anti-static Tape |

| Touchscreen or display protection | Anti-static PET Tape |

In any ESD-sensitive area, regular tape is considered a contamination and safety risk.

-

Cost vs. Risk: Why Anti-Static Tape Is Worth It

Anti-static tapes typically costs more than standard tape due to its specialized materials and production processes. However, the cost of using regular tape in an inappropriate setting can far outweigh the savings.

Imagine this scenario: You seal a batch of circuit boards with standard tape. During transit, the tape generates static that slowly damages onboard ICs. The result? Dozens of field failures, warranty claims, and loss of customer trust.

For industries where product reliability and safety are non-negotiable, anti-static tapes is not an option—it’s a necessity.

-

Conclusion

In summary, while regular tape and anti-static tapes may look similar, their functions are worlds apart. Choosing the right tape depends on your application environment, product sensitivity, and risk tolerance.

| Key Takeaway | Description |

| Use regular tape | For non-critical, general-purpose tasks |

| Use anti-static tape | For ESD-safe areas, electronics, and cleanroom use |

By understanding the difference, you can avoid unnecessary product failures, maintain compliance with ESD safety standards, and ensure consistent quality in your production processes.

Read our related blog – Types and Applications of Industrial Adhesive Tapes. For regular updates, follow us on LinkedIn.