Cushioning materials are widely used in modern industries and daily life, especially in packaging, transportation, and storage. Their main function is to protect products from external impacts, vibrations, and friction. With the diversification of market demands, the types of cushioning materials have become increasingly diverse, each offering unique characteristics suited to different application scenarios. When choosing the right cushioning material, understanding its features and advantages is crucial. This article will explore common types of cushioning materials and provide a selection guide to help readers make informed decisions.

Common Cushioning Materials

1. Foam Materials (e.g., Polyethylene Foam, Polyurethane Foam)

Foam materials are widely used in the packaging industry due to their lightweight and impact-resistant properties. Polyethylene foam and polyurethane foam are the two most commonly used types. These materials offer excellent cushioning performance, effectively absorbing external forces to protect items from shocks and vibrations. Polyethylene foam also has waterproof and moisture-resistant properties, making it suitable for transporting items sensitive to humidity, such as electronics or precision instruments. Polyurethane foam, on the other hand, is more durable, making it ideal for longer-term storage and protecting heavier items.

2. Paper-Based Cushioning (e.g., Corrugated Paper, Honeycomb Paper)

Paper-based cushioning materials are popular due to their eco-friendliness and cost-effectiveness. Corrugated paper and honeycomb paper are the most commonly used paper-based cushioning materials. Corrugated paper offers high compressive strength and cushioning properties, making it suitable for packaging general items. Honeycomb paper, with its interlaced layers of paper, has excellent shock absorption and compressive strength, often used for packaging items requiring high-strength protection, such as furniture or home appliances.

3. Bubble Wrap (Bubble Paper)

Bubble wrap is a very common cushioning material, primarily used for protecting items during packaging and transportation. The surface of bubble wrap is made up of densely packed air bubbles, which effectively disperse external pressure, reducing damage to packaged items. The advantages of bubble wrap are its lightweight, transparency (allowing easy visual inspection), and ease of cutting into various shapes and sizes. However, its cushioning performance mainly depends on the size and number of bubbles, so it is important to consider this factor when choosing bubble wrap.

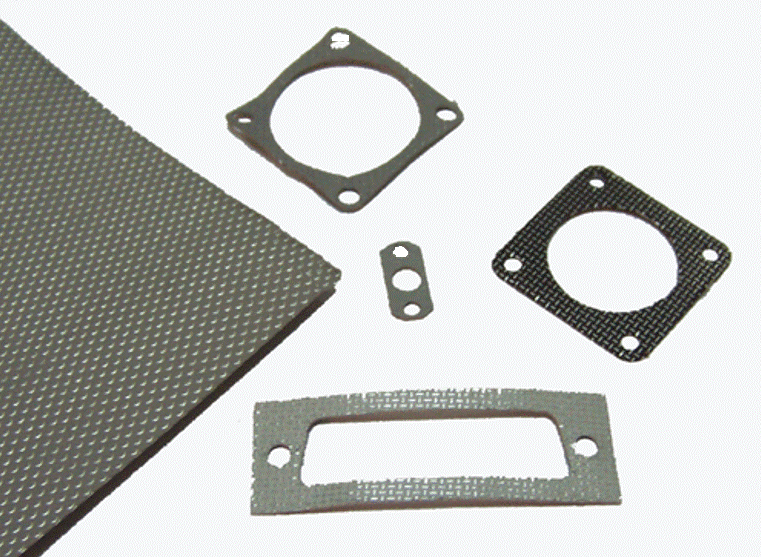

4. Rubber Pads (e.g., EPDM Rubber, Silicone Pads)

Rubber cushioning materials are known for their excellent elasticity, high-temperature resistance, and corrosion resistance. They are widely used in situations requiring long-term protection. EPDM rubber is commonly used for shock absorption and sealing in industrial machinery, while silicone pads are often used for high-temperature environments due to their superior heat resistance and anti-oxidation properties.

5. Fabric Cushioning (e.g., Cotton Fabric, Polyester Fiber)

Fabric cushioning materials are often used when gentle protection is required. They are typically used for protecting delicate and easily scratched items, such as jewelry, artwork, and glass products. Cotton fabric cushioning is commonly used to prevent scratching and abrasion of surfaces, while polyester fiber is favored for its durability and breathability, making it ideal for lightweight transport packaging.

How to Choose the Right Cushioning Material

When selecting the appropriate cushioning material, several factors need to be considered:

1. Fragility and Weight of the Item

If the item to be protected is fragile or heavy, it is essential to choose a material with high cushioning and shock resistance. In this case, options such as polyethylene foam, polyurethane foam, or honeycomb paper, which offer sturdy protection, should be prioritized. For lighter, less fragile items, bubble wrap or cotton fabric may be more suitable.

2. Cost of Packaging and Environmental Requirements

If there is a high cost constraint or if environmental standards need to be followed, paper-based cushioning materials, such as corrugated paper or honeycomb paper, can be a good choice. Paper-based materials are not only eco-friendly but also relatively cost-effective, making them ideal for large-scale production and use. While bubble wrap provides strong protection, its plastic material may not meet the environmental standards of some companies.

3. Transportation Environment

The item may be exposed to varying levels of moisture, temperature fluctuations, or other environmental factors during transportation. If the transportation environment is harsh, selecting a cushioning material with water resistance, moisture protection, and temperature resistance is critical. For example, polyethylene foam not only provides cushioning but also offers water resistance, making it ideal for transportation in humid conditions. Rubber and silicone pads are better suited for protecting items in high-temperature or extreme environments.

4. Volume of Packaging and Space Limitations

When space is limited, lightweight and compact cushioning materials, such as bubble wrap, should be chosen. It is flexible and can be cut into different shapes and sizes, making the best use of available space. For larger items requiring extra protection, honeycomb paper or polyurethane foam may be more appropriate.

5. Long-Term Storage vs. Short-Term Transportation

For long-term storage, durability is key when selecting cushioning materials. Materials like polyurethane foam, honeycomb paper, and rubber pads provide long-term protection against moisture, deformation, and aging. Bubble wrap, on the other hand, is more suitable for short-term transportation, providing effective protection against collisions and friction during transit.

Conclusion

The diversity of cushioning materials makes them suitable for a wide range of protection needs in different industries. When choosing the right cushioning material, it is essential to consider factors such as the fragility of the item, its weight, the transportation environment, and environmental requirements. By making informed choices about cushioning materials, it is possible to significantly reduce the risk of damage to goods and ensure safe transportation and storage. As technology advances and market demands evolve, the variety of cushioning materials will continue to expand, offering better protection solutions for various industries.

Read our related blog – Types and Applications of Industrial Adhesive Tapes. For regular updates, follow us on LinkedIn.